Rethinking Odour Control

New antimicrobial technologies focus on treatments for ‘permastink.’

It’s everywhere, and it’s not attractive. Permastink—the unpleasant smell that won’t wash out of textile products—has become a topic of conversation for consumers and brands alike.

Polyester and other synthetic fibers are the materials of choice for the active performance and athleisure styles consumers now wear throughout the day. Unfortunately, these synthetic fibers are perceived as being smellier than natural fibers, according to a 2008 wear trial at the University of Alberta.1

What causes permastink?

Malodors are created by the breakdown of bodily secretions into various compounds by bacteria on the skin. These compounds may include methanethiol, hydrogen sulfide, propanoic acid, and isovaleric acid. They create a chemical bond with performance fibers, locking permastink into the fabric.

Consumers are choosing to save energy by washing textile products at lower temperatures; and most performance fabrics recommend a low temperature wash. As a result, higher levels of odor-causing bacteria remain on untreated articles even after laundering.

“With permastink, garments don’t wash clean, and brands get returns,” says Lisa Owens, vice president of global textiles at Microban, a provider of antimicrobial technologies and odor control solutions. “It’s quite a problem in the industry.”

“Once odors lock into untreated synthetics, they are difficult to remove,” confirms Lee Christie Stapleton, directory of training and education at Sensory Spectrum, a global management consulting firm specializing in understanding the sensory-consumer experience. “How can we prevent that from happening?”

Killing microbes, not odors

Conventional solutions for preventing malodors on textiles focus on inhibiting the growth of odor-causing bacteria through the application of antimicrobials, either built into fiber, or applied during the textile finishing process.

While many of these successfully reduce the amount of bacteria, there is a wide variation in efficacy and durability of these formulations—and in the methods used to test and measure them.

The International Antimicrobial Council (IAC) lists five different test methods for measuring the performance of standard antimicrobial treatments: ASTM E2149-2010, AATCC 147-2004, AATCC 100-2011, ISO 20743-2007 and JISL 1902-2008. The IAC recommends that these tests be performed and verified by IAC certified labs. In general, such tests seek to assess the bactericidal activity of the test agent, as well as its inhibition of bacterial growth. But if technology supplier A uses a different test method than that used by technology supplier B, is it possible to truly compare the efficacy and durability of the two antimicrobial technologies?

Woodhead Publishing’s 2016 Antimicrobial Textiles, edited by Gang Sun, questions the validity of current test methods: “All these methods simulate optimum efficacy conditions for antimicrobial agents … But these conditions, except sportive activities, normally do not occur during practical wearing … Thus it is possible that textiles will be regarded as antimicrobial, but under practical wearing or environmental conditions, there is no, or a highly reduced, antimicrobial effect.

Another problem is that not every antimicrobial agent on the textile shows an antimicrobial action with every test method. Thus the comparability of the different methods is complicated, additionally.”

When it comes their use on apparel textiles, antimicrobial technologies have other issues, including the growth of bacterial resistance and the leaching of silver or other antimicrobial agents. But the bigger question is this: does the reduction of bacteria actually prevent, block, or remove odor on the textile?

Odor adsorption

As it turns out, there are other options.

“You have products that inhibit microbial growth. But there are other technologies that trap odor so that you don’t perceive it,” says Stapleton. “Preventing the malodor is the game in apparel. The more you can deactivate—‘eat’ the odor—you prevent it from getting to the permastink category.”

The concept of trapping, adsorbing, and eliminating odor-using, activated carbon particles or cyclodextrins is well-known to hunters and gamekeepers. In 1992 a company called Scent-Lok first developed hunting apparel containing activated charcoal to block human scent so that the game being hunted wouldn’t smell the hunters’ presence.

Owens says that carbons and cyclodextrins have shortcomings, however, such as cost, binders, discolorations and durability. A number of textile technology suppliers are now commercializing new versions of odor adsorption treatments for apparel textiles using substances such as zeolite (a mineral formed when volcanic ash reacts with alkaline groundwater) and alumina silica. The large surface area of these minerals attracts and adsorbs odor molecules.

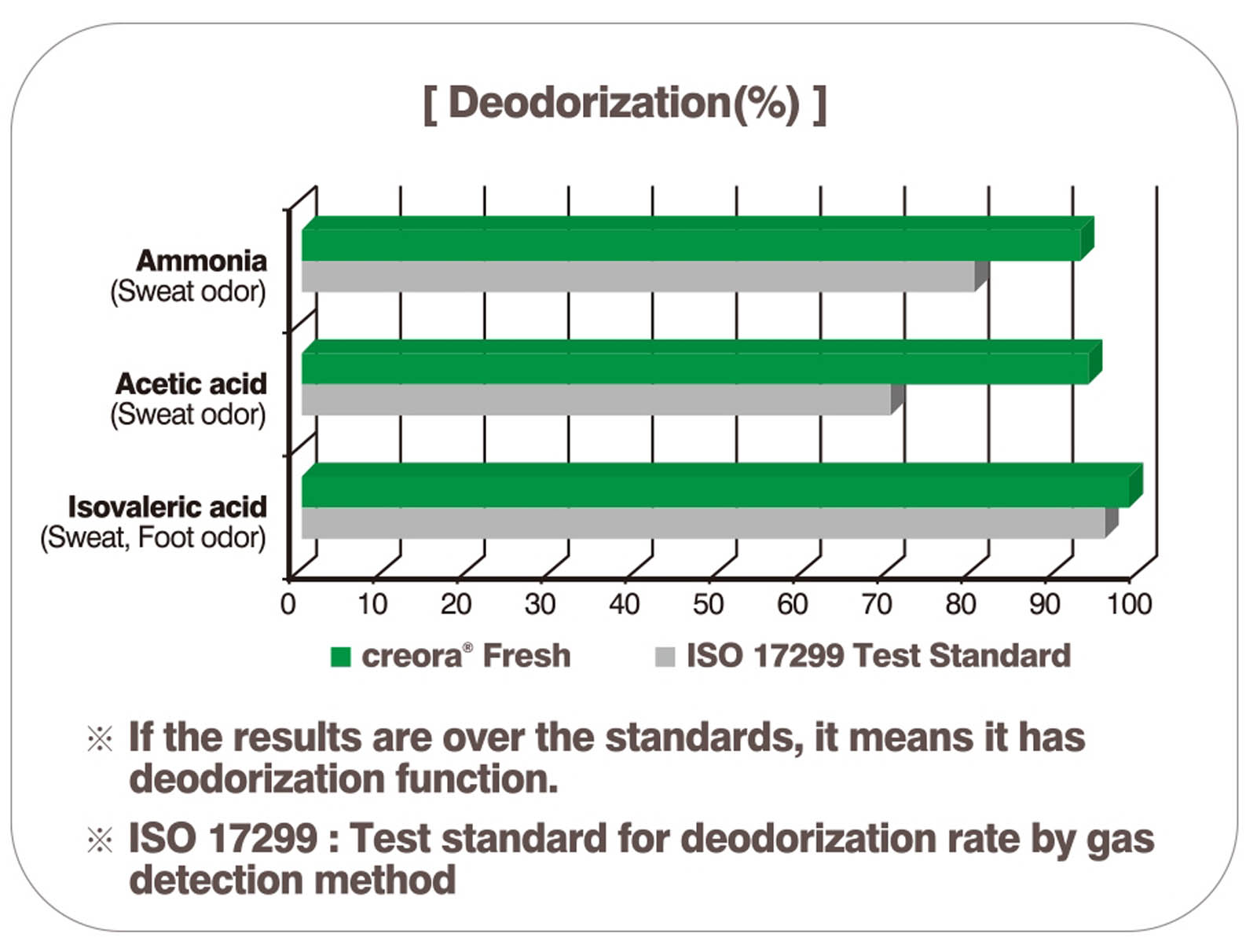

The products’ efficacy can be proven by ISO test 17299, which measures deodorization rates via gas chromatography. Standards are also established by the Japan Textile Evaluation Technology Council (JTETC).

“There’s art and there’s science when it comes to measuring odor,” says Stapleton. Sensory Spectrum recognizes three methods for evaluating odor: microbiological detection, gas chromatography, and experts who are trained to identify and evaluate the strength of odors to a scale.

“Odor compounds aren’t necessarily good or bad—it’s about the context,” Stapleton says.

A platform of odor control solutions

Based on zeolites, Sciessent’s LAVA XL™ technology attracts, adsorbs, and degrades odor molecules, avoiding saturation and allowing the product to regenerate between launderings. The bluesign®-approved formulation can be combined with Sciessent’s Agion® silver ion-based antimicrobial to create Agion XL with dual-function odor control.

Just introduced, HeiQ Fresh NKU goes beyond adsorbing body odor deriving from bacterial sweat metabolites, to sequestering volatile malodors like the “plastic” smell of polyester, new upholstery, or body hormones. The large surface of the alumina-silica microparticles in Fresh NKU immobilizes unpleasant volatile odor compounds, turning them into non-volatile, and therefore non-perceivable, odor compounds. HeiQ is also planning to release a product combining Fresh NKU with its silver-based antimicrobial technology.

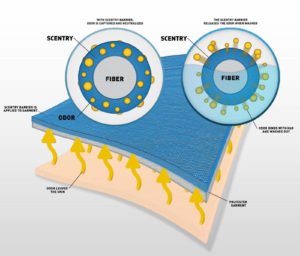

SCENTRY®, Microban’s odor-capture, product platform apparel, was introduced as a novel solution to the problem of adsorbing and trapping the body odorant compounds released by bacteria—blocking the formation of permastink, according to Brian Aylward, director of liquid formulations, R&D, at Microban. Applied as a finish, SCENTRY® creates a barrier layer on the surface of the textiles, trapping the odors and preventing them from bonding with the fabric. Washing the textile with water and detergent releases the trapped odors and recharges the treatment.

“The technology is completely different from antimicrobials, and is capable of reducing the amount of odor building up in a textile over time,” says Aylward.

SCENTRY has already been commercialized with the hunting and outdoor apparel brand Hook and Bullet, where odor adsorption commands a premium. A number of trials are being run in the performance and leisurewear segments, according to Owens. The technology has received the bluesign® system blue product designation, and can be combined with Microban antimicrobial-based technologies to provide 360˚odor control, the company says.

Microban has also developed SCENTRY for polymers, which will function as a built-in solution for consumer products using recycled PET, for example. “SCENTRY is part of a platform of customized solutions, built on our odor management expertise,” says Owens.

Korean textile producer Hyosung also sees the merit of polymers that can chemically neutralize odors in textiles. Its creora® Fresh is a functional spandex that chemically neutralizes odors such as ammonia, acetic acid, and isovaleric acid, keeping textiles smelling fresh.

Because the deodorizing function is in the polymer, it is more durable than textile coatings or finishes; and is particularly effective in textiles that come in direct contact with the skin, such as underwear, sportswear, and hosiery.

“At the consumer level, all ages continue to focus on health and wellness, with increased participation in exercise,” says Ria Stern, Hyosung textiles global marketing director. “In socks for running or walking, creora Fresh adds compression, support, and odor-neutralizing benefits with technology built into the fiber for more durability. In sports bras and underwear, we are working with brands and retailers who want to move away from having antimicrobial chemicals next to skin.”

Hyosung has also developed freshgear® polyester and MIPAN freshgear nylon as solutions for controlling odors in apparel fabrics.

What’s clear is that no one method of odor control will work in every situation. While some brands may prefer to prove odor reduction by counting bacteria in the lab, others can now choose a more sensory approach. Meanwhile, technology providers continue to develop new solutions to the problem of stinky textiles.

Debra Cobb is a freelance writer based in Greensboro, N.C, with extensive experience in the textiles industry. She is a regular contributor to Advanced Textiles Source.

1McQueen, Rachel H., et al. “Retention of axillary odour on apparel fabrics.” Journal of the Textile Institute 99.6 (2008):515-523.